أرسل لنا رسالة

jaw toe crusher wornth

Jaw Crushers JW Series Corporation

JW55 (32” x 55”) Jaw Crusher, 52” x 20’ / 24’ Feeder 200 hp (150 kW) 255 760 (231 690) 4 Axle 135,585 lbs (61,500 Kg) Portable. mplmps mpsmarketing@mpl Product specifications and prices are subject to change

进一步探索Jaw Crusher Handbook Stone Crusher PDF JXSC MineEstimate Jaw Crusher Capacity Mineral ProcessingJaw Crushers Heavy Duty FinlayJaw crushers, Stationary Jaw crusher series — SRPSANDVIK JAW CRUSHER SERIES Mining and

Industrial Solutions Jaw crushers ThyssenKrupp

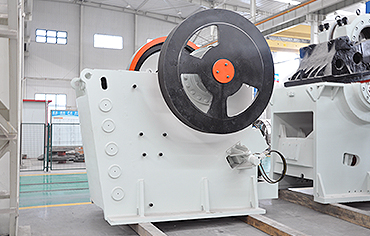

Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the

文件大小: 678KB

Liner wear in jaw crushers ScienceDirect

2003年1月1日Using a small jaw crusher, the wear of the crusher liners has been studied for different settings of the crusher. The experiments have been carried out

作者: Mats Lindqvist, Carl Magnus Evertsson

Liner wear in jaw crushers ScienceDirect

2003年1月1日The modular jaws of the developed dual pivoted jaw crusher allows flexible selection of jaw geometry, which is independent of the selectable compressive and

作者: Mats Lindqvist, Carl Magnus Evertsson

Jaw Crushers Heavy Duty Finlay

Jaw Crushers. Finlay® tracked Mobile Jaw Crushers are renown for their capabilities in the reduction and sizing of aggregates for construction materials and also recycling

Our Range of Trio® Jaw Crushers Weir

Our range of Trio® jaw crushers are designed for tough primary crushing within mining, aggregate and recycling applications. Within the mining industry, the Trio® CT Series

How Does a Jaw Crusher Work Jaw Crusher Kemper

All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary breaking surface, while a movable, “swing” jaw exerts force on

How A Jaw Crusher Works YouTube

2020年2月19日McLanahan Corporation. Jaw Crushers are most often used as the first stage in the size reduction of many different materials in a wide range of applications. They use compressive force to break

Jaw Crushers McLanahan

Jaw Crushers. Jaw Crushers are a compression-type machine that crush material between a moving piece of steel and a stationary piece of steel. They are used for primary and

Metso ® C Series™ jaw parts

C Series™ jaw crusher basic concepts The jaw crusher is a compression type crusher. Feed material is crushed between fixed and movable jaw dies. Large particles are crushed in a single layer, referred to as single-layer crushing. Smaller particles are crushed rock on rock, referred to as multi-layer crushing. C Series™ jaw crusher basic

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

2017年6月30日A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine

Our Range of Trio® Jaw Crushers Weir

Applications Our range of Trio® jaw crushers are designed for tough primary crushing within mining, aggregate and recycling applications. Within the mining industry, the Trio® CT Series jaw crusher is frequently used to process precious metals (e.g. gold, silver and palladium) and a wide spectrum of other minerals and ore.

How Does a Jaw Crusher Work Jaw Crusher

Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart. The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical

Types of Crushers: What You Need to Know Machinery Partner

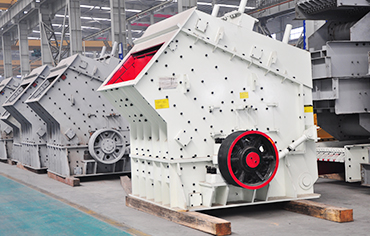

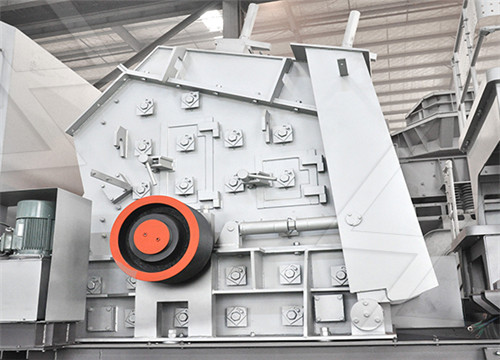

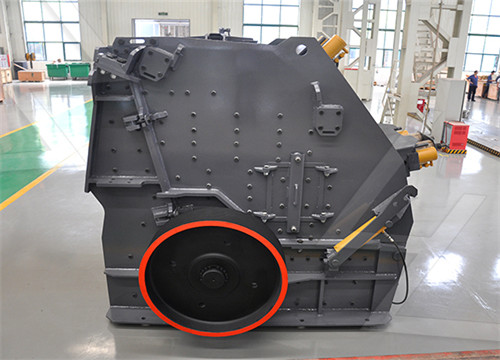

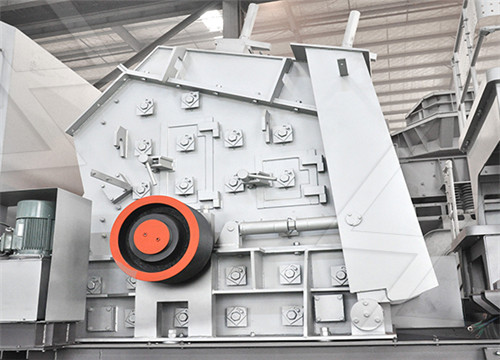

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefits.

Liner wear in jaw crushers Request PDF ResearchGate

2003年1月31日Abstract. Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these costs. Being able to predict the

Jaw Crushers Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the

Design and Construction of Rock Crushing Machine from Locally

functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher. It forms the moving side of the jaw, while the stationary or fixed jaw forms the other. It achieves its movement through the eccentric movement of the crusher main shaft. It is the back and

What Is a Jaw Crusher? Here's How It Works

2021年2月18日Jaw crushers typically use the principles of compression and friction to break materials down. They’re extremely powerful equipment that should be used with the utmost care. Jaw crushers are so powerful

Metso ® C Series™ jaw parts

The jaw crusher is a compression type crusher. Feed material is crushed between fixed and movable jaw dies. Large particles are crushed in a single layer, referred to as single-layer crushing. Smaller particles are crushed rock on rock, referred to as multi-layer crushing. Feed opening

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

2017年6月30日Determination of the optimal angle of inclination of the toggle plate, development of jaws with varying wear rate along the crushing chamber, and development of comminution energy models that take...

Our Range of Trio® Jaw Crushers Weir

Applications Our range of Trio® jaw crushers are designed for tough primary crushing within mining, aggregate and recycling applications. Within the mining industry, the Trio® CT Series jaw crusher is frequently used to process precious metals (e.g. gold, silver and palladium) and a wide spectrum of other minerals and ore.

How Does a Jaw Crusher Work Jaw Crusher

Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart. The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical

Types of Crushers: What You Need to Know Machinery Partner

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefits.

Crushing Plant FlowsheetDesign-Layout 911

2016年3月10日Crushing Plant FlowsheetDesign-Layout. In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be

Liner wear in jaw crushers Request PDF ResearchGate

2003年1月31日Abstract. Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these costs. Being able to predict the

Jaw Crushers Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology

Industrial Solutions Jaw crushers ThyssenKrupp

Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the

Liner wear in jaw crushers ScienceDirect

2003年1月1日Using a small jaw crusher, the wear of the crusher liners has been studied for different settings of the crusher. The experiments have been carried out

Liner wear in jaw crushers ScienceDirect

2003年1月1日The modular jaws of the developed dual pivoted jaw crusher allows flexible selection of jaw geometry, which is independent of the selectable compressive and

Jaw Crushers Heavy Duty Finlay

Jaw Crushers. Finlay® tracked Mobile Jaw Crushers are renown for their capabilities in the reduction and sizing of aggregates for construction materials and also recycling

Our Range of Trio® Jaw Crushers Weir

Our range of Trio® jaw crushers are designed for tough primary crushing within mining, aggregate and recycling applications. Within the mining industry, the Trio® CT Series

How Does a Jaw Crusher Work Jaw Crusher Kemper

All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary breaking surface, while a movable, “swing” jaw exerts force on

How A Jaw Crusher Works YouTube

2020年2月19日McLanahan Corporation. Jaw Crushers are most often used as the first stage in the size reduction of many different materials in a wide range of applications. They use compressive force to break

Jaw Crushers McLanahan

Jaw Crushers. Jaw Crushers are a compression-type machine that crush material between a moving piece of steel and a stationary piece of steel. They are used for primary and

Metso ® C Series™ jaw parts

C Series™ jaw crusher basic concepts The jaw crusher is a compression type crusher. Feed material is crushed between fixed and movable jaw dies. Large particles are crushed in a single layer, referred to as single-layer crushing. Smaller particles are crushed rock on rock, referred to as multi-layer crushing. C Series™ jaw crusher basic

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

2017年6月30日A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine

Our Range of Trio® Jaw Crushers Weir

Applications Our range of Trio® jaw crushers are designed for tough primary crushing within mining, aggregate and recycling applications. Within the mining industry, the Trio® CT Series jaw crusher is frequently used to process precious metals (e.g. gold, silver and palladium) and a wide spectrum of other minerals and ore.

How Does a Jaw Crusher Work Jaw Crusher

Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart. The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical

Types of Crushers: What You Need to Know Machinery Partner

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefits.

Liner wear in jaw crushers Request PDF ResearchGate

2003年1月31日Abstract. Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these costs. Being able to predict the

Jaw Crushers Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the

Design and Construction of Rock Crushing Machine from Locally

functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher. It forms the moving side of the jaw, while the stationary or fixed jaw forms the other. It achieves its movement through the eccentric movement of the crusher main shaft. It is the back and

What Is a Jaw Crusher? Here's How It Works

2021年2月18日Jaw crushers typically use the principles of compression and friction to break materials down. They’re extremely powerful equipment that should be used with the utmost care. Jaw crushers are so powerful

Metso ® C Series™ jaw parts

The jaw crusher is a compression type crusher. Feed material is crushed between fixed and movable jaw dies. Large particles are crushed in a single layer, referred to as single-layer crushing. Smaller particles are crushed rock on rock, referred to as multi-layer crushing. Feed opening

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

2017年6月30日Determination of the optimal angle of inclination of the toggle plate, development of jaws with varying wear rate along the crushing chamber, and development of comminution energy models that take...

Our Range of Trio® Jaw Crushers Weir

Applications Our range of Trio® jaw crushers are designed for tough primary crushing within mining, aggregate and recycling applications. Within the mining industry, the Trio® CT Series jaw crusher is frequently used to process precious metals (e.g. gold, silver and palladium) and a wide spectrum of other minerals and ore.

How Does a Jaw Crusher Work Jaw Crusher

Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart. The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical

Types of Crushers: What You Need to Know Machinery Partner

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefits.

Crushing Plant FlowsheetDesign-Layout 911

2016年3月10日Crushing Plant FlowsheetDesign-Layout. In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be

Liner wear in jaw crushers Request PDF ResearchGate

2003年1月31日Abstract. Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these costs. Being able to predict the

Jaw Crushers Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology