أرسل لنا رسالة

replacements parts of ball mill

Ball mill trunnion replacement

Drawing on years of experience and process knowledge, our trunnion replacement service combines our state-of-the-art trunnion design, high-quality parts and expert onsite installation teams to ensure reliable mill operation. Ball mill trunnion replacement

进一步探索Ball Mill Trunnion [PDF Document]Premium spare parts for trunnion-supported mill Step by Step Guide to Replace Ball Mill Liners Qiming 17 Signs of Problems with Ball Mills: Quickly Remove Repair Ball Mill Discharge Trunnion Crack

Ball Mill Parts For Sale Quality Ball Mill Components

1. ball mill shell 2. ball mill end cover liner 3. feeding port 4. ball mill bearing 5. ball mill end cover 6. frame 7. driving system frame 8. ball mill pinion 9. ball mill reducer 10. ball mill coupler 11. ball mill motor 12.

Ball Mill Maintenance Procedure Guide

1. The transmission device, main bearing shaft, feeding part and discharging part of the ball mill are recommended to be overhauled once a year. Pay attention to the maintenance

文件大小: 182KB

Ball Mill MaintenanceInstallation Procedure 911

Ball Mill Maintenance Manualon Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FoundationGroutingBall Mill Sole PlatePinion BearingsMill Trunnion BearingsMill Shell LinerHead LinersHow to Mount A Ball Mill

Adequate foundations for any heavy equipment, and in particular grinding mills, are extremely important to assure proper operation. The foundation should preferably be in one piece, that is, with a reinforced slab footing (so called “mat”) extending under both trunnion bearing foundations as well as the pinion bearing foundation. If possible or pra...

A Guide to Ball Mill Liner Replacement and Maintenance

When to Replace Ball Mill Liners. Knowing when to replace ball mill liners is crucial to the performance of the mill. Here are a few signs that it may be time to replace your liners:

作者: Mancy

Ball Mill an overview ScienceDirect Topics

Displacement of balls in mill. n=42.3Dm where Dmis the mill diameter in meters.

Ball Mill Replacement Parts ProductsSuppliers

Find Ball Mill Replacement Parts related suppliers, manufacturers, products and specifications on GlobalSpec a trusted source of Ball Mill Replacement Parts

Ball Mill Working Principle And Main Parts GitHub Pages

34 行The main part of the ball mill mainly include feeding part, discharging part, a rotary part, a transmission part (reducer, small gear, motors, electrical control) and other parts. Hollow shaft adopts steel

Ball Mills 911 Metallurgist

2017年2月13日Ball-Rod Mills, based on 4″ liners and capacity varying as 2.6 power of mill diameter, on the 5′ size give 20 per cent increased capacity; on the 4′ size, 25 per cent; and on the 3′ size, 28 per cent.

Steel Ball Mills and Milling Equipment Paul O Abbé

Paul O Abbé Equipment Company is a manufacturer New Steel Ball Mills and Milling Equipment. Call 800-524-2188 or request a quote to get started.

Ball mill trunnion replacement

3. Mill head 4. Trunnion liner 5. Bearing liner The best a ball mill can get has installed almost 4000 ball mills at locations worldwide which has given us a unique insight into the stresses and strains arising out of ball mill operations. The large alternating stresses placed on ball mill trunnions and heads are a great example.

Ball Mill Maintenance Procedure Guide

1. The transmission device, main bearing shaft, feeding part and discharging part of the ball mill are recommended to be overhauled once a year. Pay attention to the maintenance of the motor and reducer at ordinary times, and the large and small gears must be replaced and repaired if they are severely broken, lost teeth or worn.

Ball Mill Parts For Sale Quality Ball Mill

1. ball mill shell 2. ball mill end cover liner 3. feeding port 4. ball mill bearing 5. ball mill end cover 6. frame 7. driving system frame 8. ball mill pinion 9. ball mill reducer 10. ball mill coupler 11. ball mill motor 12.

Ball Mill MaintenanceInstallation Procedure

2016年10月19日All burrs should be carefully removed by filing or honing. Unless otherwise arranged for, the mill has been completely assembled in our shop. Before dismantling, the closely fitted parts were match

Ball Mill an overview ScienceDirect Topics

where d b.max is the maximum size of feed (mm); σ is compression strength (MPa); E is modulus of elasticity (MPa); ρb is density of material of balls (kg/m 3); D is inner diameter of the mill body (m).. Generally, a maximum allowed ball size is situated in the range from D /18 to D/24.. The degree of filling the mill with balls also influences productivity of the

Ball Mill Working Principle And Main Parts GitHub

The main part of the ball mill mainly include feeding part, discharging part, a rotary part, a transmission part (reducer, small gear, motors, electrical control) and other parts. Hollow shaft adopts steel castings, the liner is

Raymond® OEM Replacement Parts and Service

Many equipment replacement parts fall into the non-wear category. These range from small machined components such as journal heads to large machined mill bases. A number of these items are forged and casted

Replacement Parts Sherline Products

Replacement Parts Page may take a few seconds to load . Need help finding a specific part? See our guide on how to find part numbers the easy way. Name SKU Accordion Way Cover Set for Ball Screw Mills quantity. Add to cart. Add to Wishlist Remove from Wishlist. Add to Wishlist. 2" Industrial Handwheel Inch: 67018 $ 21.84: 2" Industrial

الكسارة الأساسية للإنتاج الكلي

استخراج المغنيسيوم في الدولوميت

طاحونة هيدروكول لكسر الاحجار

حصان 1103 الطاحن الفحم

كسارة من الدرجة الثانية مقعر السعر

ما هو وكيل الترابط لمطاحن الفحم

أوهيو بوبكات كسارة الحجر

أنواع مختلفة من السيور الناقلة

مجموعه سنگ های سنگی مصر برای فروش

اسماء مقاطعات التعدين بجنوب افريقيا

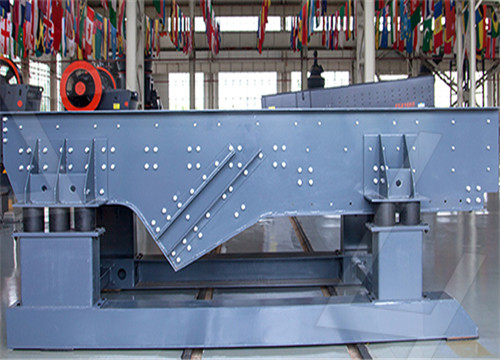

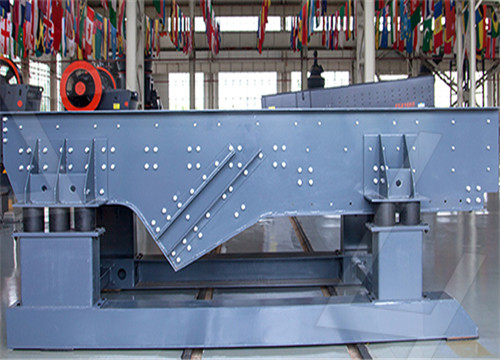

الثقيلة اهتزازي غربال شاكر نوع

الشركات المصنعة لأنظمة الحزام الناقل في الهند

أفضل كسارة الصخور في Europebest كسارة الصخور في الهند

أسعار مسحوق الحجر الجيري في جنوب أفريقيا

ما هي المعدات إنتاج مسحوق الجير جيدة

همراه بتن برای فروش استفاده می شودسنگ شکن

المرصوفة بالحجارة تأثير محطم

hs كود طحن طحن machinehs كود دعم مجمع

آلة كسارة الصخور المدمجة

كسارة خرسانة متنقلة للبيع في الجزائر

كربيد 3 4 كرة مطحنة نهاية

الكامل محجر كسارة سعر المصنع

قدم المشروع على رمل م

شبكة اختيار كسارة

ماكينات مصنع بالر لسحق الخبث الفرن في البنجاب

غربال صغير الترابية للبيع

Ball Mill Parts For Sale Quality Ball Mill Components

1. ball mill shell 2. ball mill end cover liner 3. feeding port 4. ball mill bearing 5. ball mill end cover 6. frame 7. driving system frame 8. ball mill pinion 9. ball mill reducer 10. ball mill coupler 11. ball mill motor 12.

Ball Mill Maintenance Procedure Guide

1. The transmission device, main bearing shaft, feeding part and discharging part of the ball mill are recommended to be overhauled once a year. Pay attention to the maintenance

Ball Mill MaintenanceInstallation Procedure 911

Ball Mill Maintenance Manualon Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FoundationGroutingBall Mill Sole PlatePinion BearingsMill Trunnion BearingsMill Shell LinerHead LinersHow to Mount A Ball Mill

Adequate foundations for any heavy equipment, and in particular grinding mills, are extremely important to assure proper operation. The foundation should preferably be in one piece, that is, with a reinforced slab footing (so called “mat”) extending under both trunnion bearing foundations as well as the pinion bearing foundation. If possible or pra...

A Guide to Ball Mill Liner Replacement and Maintenance

When to Replace Ball Mill Liners. Knowing when to replace ball mill liners is crucial to the performance of the mill. Here are a few signs that it may be time to replace your liners:

Ball Mill an overview ScienceDirect Topics

Displacement of balls in mill. n=42.3Dm where Dmis the mill diameter in meters.

Ball Mill Replacement Parts ProductsSuppliers

Find Ball Mill Replacement Parts related suppliers, manufacturers, products and specifications on GlobalSpec a trusted source of Ball Mill Replacement Parts

Ball Mill Working Principle And Main Parts GitHub Pages

34 行The main part of the ball mill mainly include feeding part, discharging part, a rotary part, a transmission part (reducer, small gear, motors, electrical control) and other parts. Hollow shaft adopts steel

Ball Mills 911 Metallurgist

2017年2月13日Ball-Rod Mills, based on 4″ liners and capacity varying as 2.6 power of mill diameter, on the 5′ size give 20 per cent increased capacity; on the 4′ size, 25 per cent; and on the 3′ size, 28 per cent.

Steel Ball Mills and Milling Equipment Paul O Abbé

Paul O Abbé Equipment Company is a manufacturer New Steel Ball Mills and Milling Equipment. Call 800-524-2188 or request a quote to get started.

Ball mill trunnion replacement

3. Mill head 4. Trunnion liner 5. Bearing liner The best a ball mill can get has installed almost 4000 ball mills at locations worldwide which has given us a unique insight into the stresses and strains arising out of ball mill operations. The large alternating stresses placed on ball mill trunnions and heads are a great example.

Ball Mill Maintenance Procedure Guide

1. The transmission device, main bearing shaft, feeding part and discharging part of the ball mill are recommended to be overhauled once a year. Pay attention to the maintenance of the motor and reducer at ordinary times, and the large and small gears must be replaced and repaired if they are severely broken, lost teeth or worn.

Ball Mill Parts For Sale Quality Ball Mill

1. ball mill shell 2. ball mill end cover liner 3. feeding port 4. ball mill bearing 5. ball mill end cover 6. frame 7. driving system frame 8. ball mill pinion 9. ball mill reducer 10. ball mill coupler 11. ball mill motor 12.

Ball Mill MaintenanceInstallation Procedure

2016年10月19日All burrs should be carefully removed by filing or honing. Unless otherwise arranged for, the mill has been completely assembled in our shop. Before dismantling, the closely fitted parts were match

Ball Mill an overview ScienceDirect Topics

where d b.max is the maximum size of feed (mm); σ is compression strength (MPa); E is modulus of elasticity (MPa); ρb is density of material of balls (kg/m 3); D is inner diameter of the mill body (m).. Generally, a maximum allowed ball size is situated in the range from D /18 to D/24.. The degree of filling the mill with balls also influences productivity of the

Ball Mill Working Principle And Main Parts GitHub

The main part of the ball mill mainly include feeding part, discharging part, a rotary part, a transmission part (reducer, small gear, motors, electrical control) and other parts. Hollow shaft adopts steel castings, the liner is

Raymond® OEM Replacement Parts and Service

Many equipment replacement parts fall into the non-wear category. These range from small machined components such as journal heads to large machined mill bases. A number of these items are forged and casted

Replacement Parts Sherline Products

Replacement Parts Page may take a few seconds to load . Need help finding a specific part? See our guide on how to find part numbers the easy way. Name SKU Accordion Way Cover Set for Ball Screw Mills quantity. Add to cart. Add to Wishlist Remove from Wishlist. Add to Wishlist. 2" Industrial Handwheel Inch: 67018 $ 21.84: 2" Industrial