أرسل لنا رسالة

mps roller mill pressure frame damping device

Rolling Bearings in Vertical Mills Built by Gebr. Pfeiffer AG, Germany

MPS mills are equipped with an external material feed system to reduce pressure losses. Thanks to the optimal design of the nozzle ring, a fluidized bed above the nozzle ring is

COAL GRINDING IMPS: more than meets the eye Gebr. Pfeiffer

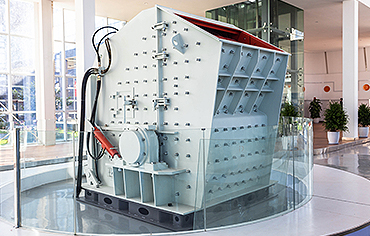

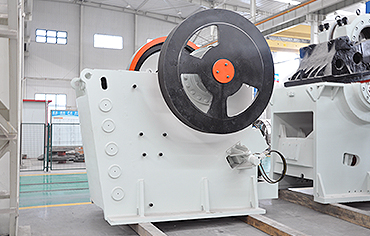

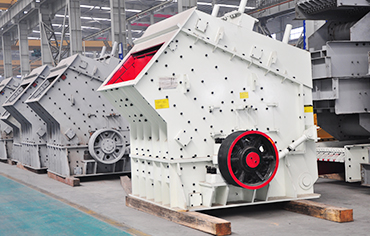

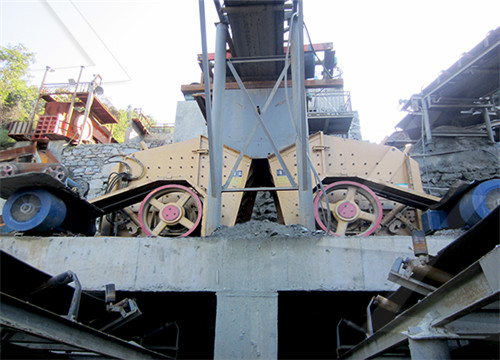

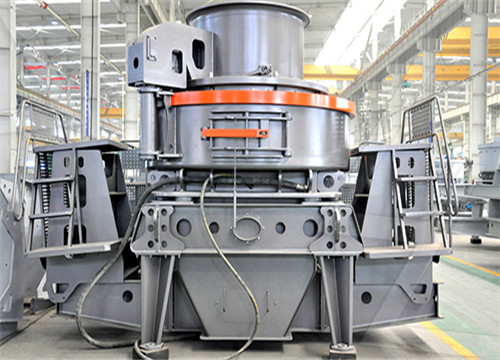

The MPS vertical roller mill is characterised by its statically-determinate system which consists of a pressure frame, three rollers and three external pull rods, and ensures the

Coal mill, gypsum mill, clay mill, etc. Pfeiffer MPS mills

Reprint from ZKG 3

flow rate the mill control range is between 30 and 100 %. Part-load operation may become neces-sary as a result of load variations in injection-type grinding mills installed in power

MPS vertical roller mills for slag and slag cements

2007年11月1日The statically determined 3-roller-system, which is pressed against the grinding bed by a pressure frame, external pull rods and the hydraulic system, is a

Cement mills and raw mills for high throughput rates

Space-saving twin support for largest possible maintenance access. 7. Up to six MultiDrive® modules ensuring active redundancy. 8. Drive modules can be pulled out separately for

The Hydraulic Roller Press offers cost-saving grinding

The Hydraulic Roller Press’s exceptional design helps to improve operational efficiency and reduces energy consumption. The hinged frame allows easy removal of the rollers for

sbm/sbm mps roller mill external pull rods.md at main GitHub

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Sensors Free Full-Text Squeeze-Film Air Damping of a

2017年4月16日Given that the frequency response of the electric bearing is critically dependent on the damping coefficients at atmospheric pressure, a solution to the air

CNA Roller press damping device and roller press

The invention provides a roller press damping device. The roller press damping device is applied to a roller press on which an action roller and a speed reducer for driving the

COAL GRINDING IMPS: more than meets the eye Gebr. Pfeiffer

pressure frame, three rollers . and three external pull rods, and ensures the load is uniformly distributed to the grinding table. The table is driven by an electric motor and a gearbox. During start-up and maintenance the rollers can be lifted by tensioning cylinders.A high-efficiency SLS classifier is mounted above .

(PDF) MPS mills for coal grinding ResearchGate

2014年1月1日January 2002 ZKG INTERNATIONAL. H. Gilabert. Since the beginning of 2002, Industrias Rocacem S.A has been operating an MPS 4250 BC roller mill at their Latacunga grinding plant in Ecuador. The

Reprint from ZKG 3

flow rate the mill control range is between 30 and 100 %. Part-load operation may become neces-sary as a result of load variations in injection-type grinding mills installed in power plants, changing fuel qualities and a grindability other than that specified in the design criteria for the mill. The MPS vertical roller mill is characterized by

Modelling of vertical spindle mills. Part 2: Integrated models

2015年3月1日Plant survey data from an E-mill (ball-race) and MPS mill (roller-race), both including internal streams and external sampling, and the CKP mill (roller-race without internal classification) were used to calibrate the VSM sub

Pulverizers 101: Part I POWER Magazine

2011年8月1日In essence, the performance of a pulverizer is a delicate balancing act between the HGI, fuel fineness, and throughput. 1. A typical MPS-89 pulverizer found in many coal-fired power plants

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016年10月5日The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials. The overall grinding circuit efficiency and stability are improved. The maintenance cost of the ball mill is reduced as the lifetime of grinding media and partition grates is extended. 2.5.

MPS vertical roller mills for slag and slag cements

2007年11月1日Operating data. The first industrial-scale vertical roller mill for slag cement, an MPS 3750 C, went into operation in Hannover 25 years ago 1 and is still in operation today (Figure 3). The capacity of this mill ranges from 60t/h slag with 4100cm²/g to 70t/h CEM III A or 45t/h CEM III B with slag content between 50–80% and fineness of

Cement mills and raw mills for high throughput rates Gebr. Pfeiffer

Space-saving twin support for largest possible maintenance access. 7. Up to six MultiDrive® modules ensuring active redundancy. 8. Drive modules can be pulled out separately for operation with n-1 drive modules. Technical data. Throughput rate.

Seismic Design of Steel Moment-Resisting Frames with Damping Systems

In the comparative design example, the frame with damping devices has 60% of the weight for frames without damping devices. Similar to the preceding design example, the proposed design procedure can design damping devices effectively to reduce seismic demand on the seismic-force-resisting system with better efficiency, which is owing to

Competence in cement

material is ground by pressure and shear. The compression forces required for pressure frame external pull rods fine product feed material hot gas reject material maintenance drive. 10 11 Pfeiffer MPS roller mill. 14 15 175 150

COAL GRINDING IMPS: more than meets the eye Gebr. Pfeiffer

pressure frame, three rollers . and three external pull rods, and ensures the load is uniformly distributed to the grinding table. The table is driven by an electric motor and a gearbox. During start-up and maintenance the rollers can be lifted by tensioning cylinders.A high-efficiency SLS classifier is mounted above .

(PDF) MPS mills for coal grinding ResearchGate

2014年1月1日The MPS vertical roller mill is characterized by its statically determinate system which consists of the pressure frame, the 3 rollers and the 3 external pull rods and ensures that the...

Reprint from ZKG 3

flow rate the mill control range is between 30 and 100 %. Part-load operation may become neces-sary as a result of load variations in injection-type grinding mills installed in power plants, changing fuel qualities and a grindability other than that specified in the design criteria for the mill. The MPS vertical roller mill is characterized by

Modelling of vertical spindle mills. Part 2: Integrated models

2015年3月1日Plant survey data from an E-mill (ball-race) and MPS mill (roller-race), both including internal streams and external sampling, and the CKP mill (roller-race without internal classification) were used to calibrate the VSM sub

Pulverizers 101: Part I POWER Magazine

2011年8月1日In essence, the performance of a pulverizer is a delicate balancing act between the HGI, fuel fineness, and throughput. 1. A typical MPS-89 pulverizer found in many coal-fired power plants

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016年10月5日The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials. The overall grinding circuit efficiency and stability are improved. The maintenance cost of the ball mill is reduced as the lifetime of grinding media and partition grates is extended. 2.5.

MPS vertical roller mills for slag and slag cements

2007年11月1日Operating data. The first industrial-scale vertical roller mill for slag cement, an MPS 3750 C, went into operation in Hannover 25 years ago 1 and is still in operation today (Figure 3). The capacity of this mill ranges from 60t/h slag with 4100cm²/g to 70t/h CEM III A or 45t/h CEM III B with slag content between 50–80% and fineness of

Cement mills and raw mills for high throughput rates Gebr. Pfeiffer

Space-saving twin support for largest possible maintenance access. 7. Up to six MultiDrive® modules ensuring active redundancy. 8. Drive modules can be pulled out separately for operation with n-1 drive modules. Technical data. Throughput rate.

Seismic Design of Steel Moment-Resisting Frames with Damping Systems

In the comparative design example, the frame with damping devices has 60% of the weight for frames without damping devices. Similar to the preceding design example, the proposed design procedure can design damping devices effectively to reduce seismic demand on the seismic-force-resisting system with better efficiency, which is owing to