أرسل لنا رسالة

how to carry out maintenance of cement mill in cement industry

Analysis of Raw Mill Machines Maintenance in Cement Industry

2020年5月1日To find out the frequency of damage to the machine or the time interval between damage to the tool (MTBF) and the length of time used to repair the tool (MTTR), the Total Productive Maintenance (TPM) method is used to perform maintenance by

Analysis of Raw Mill Machines Maintenance in Cement

2020年5月30日Abstract Cement processing plan is a state-owned enterprise engaged in the cement industry. The problem that this

BALL MILL MAINTENANCE The Cement Institute

2023年4月17日This module will cover the different types of fans used in the cement industry, applications, maintenance, and troubleshooting. Ball Mill Dust Collector.

PAPER OPEN ACCESS Analysis of Raw Mill Machines Maintenance

Maintenance activities have been carried out at the cement processing company. However, at sometime there are still engine failures that occur. This condition certainly

MAINTENANCE IN THE CEMENT INDUSTRY

Maintenance in the cement industry is one of the contributor of the production cost and represent typical 15 25 per cent of total

Managing the maintenance inventory of a cement

2013年5月31日One approach to managing maintenance inventories efficiently is to implement a classification of the inventory items in terms of their criticality to the cement production process.

Maintenence in Cement Industry Project PDF Business

TYPES OF MAINTENANCE SYSTEMS: 1) Condition Based Maintenance 2) Preventive Maintenance 3) Planned Maintenance 4) Break down Maintenance CONDITION BASED MAINTENANCE: Condition-based

Digitization and the future of the cement plant McKinsey

2020年9月16日The cement industry is being hit hard by the COVID-19 pandemic, with global demand for cement expected to decline by 7 to 8 percent in 2020—though these

Systematic and Condition Based Maintenance of Vertical Mill at

2021年5月20日this channel Designed to spread All you want to know about the cement industry, including mechanics, production, problems related to equipment and methods of...

Cement Mills Optimization--- The Quality Perspective

2019年6月13日1. Alite and Belite Content: Higher the Alite percentage and lower the Belite percentage easy will be the clinker grindabiliy and hence more mill output and lower power consumption.

Analysis of Raw Mill Machines Maintenance in Cement Industry

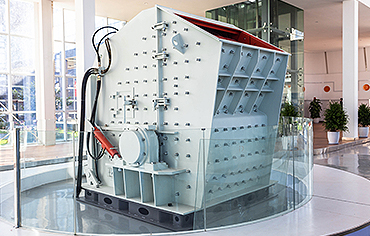

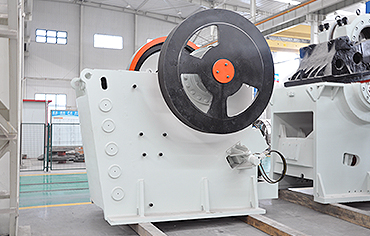

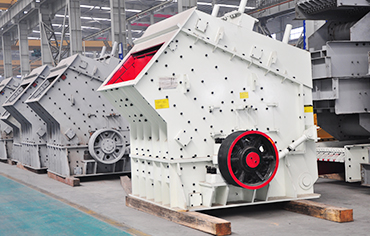

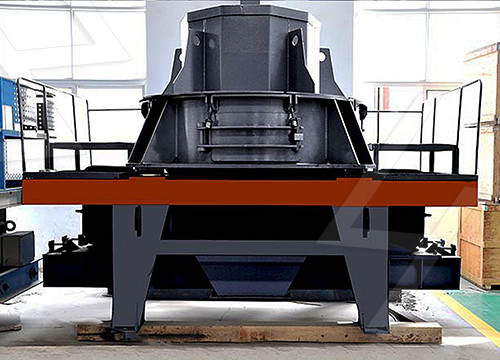

2020年5月1日The machines used in cement production at the factory include raw mill machines, kiln machines, and cement mill machines. The more often a machine is damaged, the average time between failures of a machine is lower. So that it can cause the production process is hampered. In this study, the engine studied was the Raw Mill

Industrial : Optimization for the Cement Industry ABB

cement mill operations in four ways: • More consistent quality (grade). The continual monitoring of the mill loading and the adjustment of the feed and separator results in reduced variations in cement grade. This has the added benefit of a more consistent product quality. The control strategy is designed to respond to disturbances in the

BALL MILL MAINTENANCE The Cement Institute

2023年4月17日This module will cover the different types of fans used in the cement industry, applications, maintenance, and troubleshooting. Ball Mill Dust Collector. Introduction. Dust collection systems are the most widely used engineering control technique by cement processing plants to control dust and decrease workers’ exposure to

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

on the quality requirement. Feed material is ground in the ball mill, discharged and fed to a classifier with the help of bucket elevator for classification of the ground cement into two a streams coarse and fines. The coarse fraction is sent back to the mill and the fines are collected in cyclones and / or a baghouse as finished product.

PREDICTIVE/ PREVENTIVE MAINTENANCE IN CEMENT INDUSTRY

2022年10月28日Process of Preventive Maintenance in Cement Plant: Vibration reading (Horizontal/Vertical/Axial) of equipment can be collected. On the basis of real-time triaxial vibrations, a trend can be...

Cement Environmental Directive Holcim

• In case of AFR processing in the coal mill (co-grinding), the impact on VOC emissions must be assessed based on the material characteristics. If an increase of VOC emissions is expected, a spot measurement should be conducted at the coal mill stack during AFR co-grinding to verify the impact.

Predictive Maintenance Checklist for Cement Industry

2021年8月24日In the cement industry, operating costs saving is directly linked to keeping equipment running for longer duration and more efficiently, reducing risk of unexpected shutdowns, and optimizing...

Failure analysis of a ball mill located in a cement’s production line

2022年8月1日It is divided into two chambers: the first is 3.75 m long, with a maximum ball diameter of 80 mm and a density of 30%; the second chamber is 8.675 m long, with a maximum ball diameter of 40 mm and a maximum load volume of 27.7%. The resulting cement production is 45 tons per hour. The mill under analysis has four maintenance

Predictive maintenance anomaly detection in cement industry

2022年6月23日It’s also important to consider the cost of carrying out predictive maintenance. PdM can be expensive, so it’s important to weigh the benefits against the costs. In some cases, it may be more cost-effective to carry out preventive maintenance instead. That requires a significant amount of data and processing power.

How many employees require a Cement Plant? LinkedIn

2020年8月2日Trough my 29 years of career in the cement industry I have been witness of (Operation and Maintenance) of the plant are carry out for outsourcing ( 1 Raw Mill :1 Kiln :1 Cement Mill

Analysis of Raw Mill Machines Maintenance in Cement Industry

2020年5月1日The machines used in cement production at the factory include raw mill machines, kiln machines, and cement mill machines. The more often a machine is damaged, the average time between failures of a machine is lower. So that it can cause the production process is hampered. In this study, the engine studied was the Raw Mill

Industrial : Optimization for the Cement Industry ABB

cement mill operations in four ways: • More consistent quality (grade). The continual monitoring of the mill loading and the adjustment of the feed and separator results in reduced variations in cement grade. This has the added benefit of a more consistent product quality. The control strategy is designed to respond to disturbances in the

Cement Environmental Directive Holcim

• In case of AFR processing in the coal mill (co-grinding), the impact on VOC emissions must be assessed based on the material characteristics. If an increase of VOC emissions is expected, a spot measurement should be conducted at the coal mill stack during AFR co-grinding to verify the impact.

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

The purpose of the central diaphragm is to retain the grinding media in their respective chambers, provide adequate opening for the airflow and, in some special types, regulate the feed to the second compartment. The mill is equipped

PREDICTIVE/ PREVENTIVE MAINTENANCE IN CEMENT INDUSTRY

2022年10月28日Process of Preventive Maintenance in Cement Plant: Vibration reading (Horizontal/Vertical/Axial) of equipment can be collected. On the basis of real-time triaxial vibrations, a trend can be...

Predictive maintenance anomaly detection in cement industry

2022年6月23日It’s also important to consider the cost of carrying out predictive maintenance. PdM can be expensive, so it’s important to weigh the benefits against the costs. In some cases, it may be more cost-effective to carry out preventive maintenance instead. That requires a significant amount of data and processing power.

Cement ProcessEnergy Saving ECCJ

Cementsilo Shippingpier ViewofJapaneseC Coal yard Water Layoutof one Japanese cement em factory entFactory Electrostatic Precipitator Raw mill crusher ChemicalComposition required aw for Materials production Base: 1 ton of cement and of Energy tonofCement Dry Process C Silica em Raw entProduction Clinker Process

Failure analysis of a ball mill located in a cement’s production line

2022年8月1日It is divided into two chambers: the first is 3.75 m long, with a maximum ball diameter of 80 mm and a density of 30%; the second chamber is 8.675 m long, with a maximum ball diameter of 40 mm and a maximum load volume of 27.7%. The resulting cement production is 45 tons per hour. The mill under analysis has four maintenance

Cement Milling

Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls). Grinding clinker requires a lot of energy. How easy a particular clinker is to grind ("grindability") is not always easy to predict, but large clusters of belite due to coarse silica in the feed

Reducing energy consumption of a raw mill in cement industry

2012年6月1日In this study, the first and second law analysis of a raw mill is performed and certain measures are implemented in an existing raw mill in a cement factory in order to reduce the amount of energy consumption in grinding process. The first and second law efficiencies of the raw mill are determined to be 61.5% and 16.4%, respectively.